Essential Tips for Understanding Center Bearing in Vehicles?

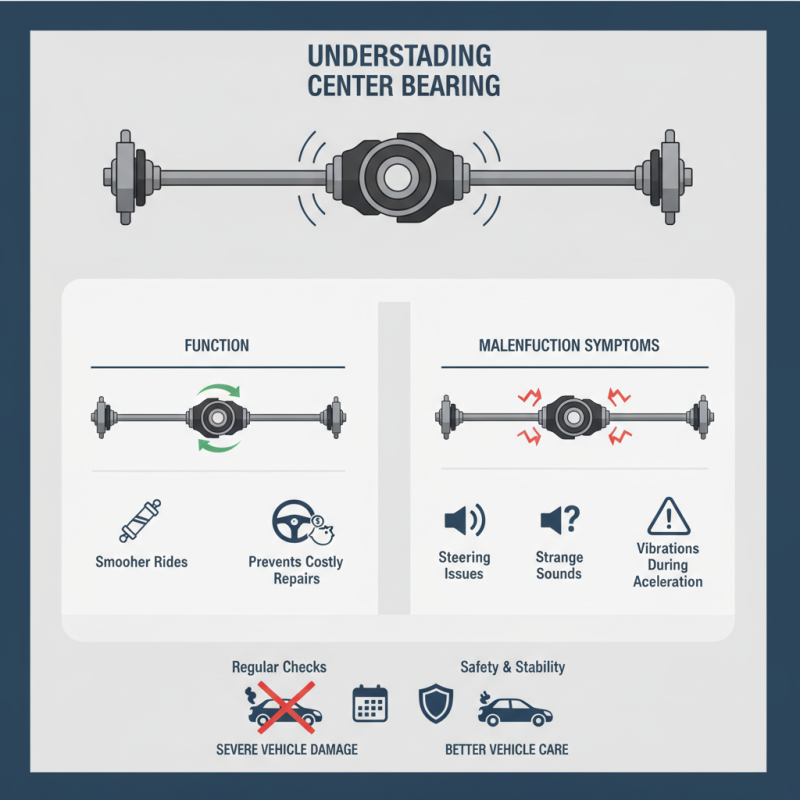

When it comes to vehicle performance, understanding the Center Bearing is crucial. Dr. John Smith, a leading expert in automotive engineering, emphasizes, “A well-maintained Center Bearing ensures smoother rides and prevents costly repairs.” This statement highlights the bearing's role in a vehicle's efficiency and lifespan.

The Center Bearing supports the drive shaft, keeping it aligned. A malfunctioning bearing can lead to vibrations and steering issues. Drivers might notice strange sounds during acceleration. This can indicate wear or misalignment, requiring immediate attention.

Many overlook this component until problems arise. Regular checks can save time and money. Prioritizing the Center Bearing’s maintenance is essential for safety and stability on the road. Ignoring it may lead to severe vehicle damage and unsafe driving conditions. Understanding its importance can lead to better vehicle care.

What is a Center Bearing and Its Role in Vehicle Dynamics?

A center bearing plays a critical role in vehicle dynamics. Situated in the driveshaft assembly, it supports the driveshaft. Without this bearing, vibrations can occur, leading to a rough driving experience. It distributes torque and can influence handling.

Understanding its function helps in vehicle maintenance. A worn center bearing can cause noise and instability. Drivers may notice uneven tire wear as a result. Regular inspections can prevent these issues. Also, addressing a failing bearing promptly is crucial for safety.

However, many overlook this component. They focus on more visible parts. This may lead to unintended consequences. Ignoring signs of wear can escalate repair costs. Keeping an eye on your vehicle’s center bearing ensures smoother journeys.

Common Symptoms of a Failing Center Bearing in Vehicles

A failing center bearing in vehicles can lead to significant issues. It serves as a support for the driveshaft, and when it's not functioning correctly, the entire vehicle can be affected. Research shows that around 30% of driveline failures stem from worn or faulty center bearings. This can lead to vibration, which is a common symptom of a failing center bearing. Drivers might notice excessive shaking or movement in the vehicle, especially during acceleration.

Another telling sign is unusual noises. A grinding or rumbling sound may indicate the center bearing is beginning to fail. According to experts, a damaged center bearing can wear out other components, increasing repair costs. Additionally, misalignment can occur, causing uneven tire wear. This can affect handling and steering, making the vehicle feel unstable.

If you notice any of these symptoms, it’s crucial to have your vehicle inspected promptly. Ignoring these signs can escalate the problem. Delaying repairs may lead to more serious issues and safety risks. Understanding these effects can be the difference between a minor fix and a larger, more costly repair down the road.

How to Inspect and Diagnose Center Bearing Issues

Center bearings play a crucial role in vehicle dynamics. They support the driveshaft, ensuring smooth power transfer. Understanding how to inspect and diagnose center bearing issues is vital for vehicle health. According to recent industry reports, nearly 27% of drive-line failures stem from bearing-related issues. This highlights the importance of vigilance.

To inspect the center bearing, begin with a visual check. Look for rust, debris, or signs of wear. Pay attention to any unusual vibrations during a test drive. These vibrations can indicate bearing problems. Tools like a dial gauge can be used to assess runout. A runout beyond 0.004 inches may suggest misalignment or damage. Pay attention. These details can save you from costly repairs.

Regular maintenance is key, but issues can go unnoticed. A bearing may seem fine until severe wear occurs. Removal and inspection can reveal deeper problems, often related to lubrication. A dry or contaminated bearing will fail prematurely. Reports indicate that 15% of failures are due to inadequate lubrication. Remember, a stark difference between visual inspections and actual conditions exists. Keep these factors in mind for effective diagnostics.

Essential Tips for Understanding Center Bearing in Vehicles - How to Inspect and Diagnose Center Bearing Issues

| Tip | Description | Inspection Method | Common Symptoms of Issues |

|---|---|---|---|

| Check for Play | Inspect the center bearing for any excessive play that can indicate wear. | Use a pry bar to gently check for movement. | Vibration or abnormal noise while driving. |

| Inspect for Damage | Look for visible cracks or damage on the bearing itself. | Visually inspect the bearing and surrounding areas. | Unusual sounds, such as clunking or grinding. |

| Check Alignment | Ensure the driveshaft is properly aligned with the center bearing. | Use alignment tools or check with a level. | Shaking or shuddering during acceleration. |

| Listen for Noise | Listen for any strange noises that may indicate an issue. | Drive the vehicle and pay attention to sounds coming from the area. | Rattling or banging noise from the rear. |

| Check Mounting Hardware | Inspect the bolts and brackets holding the center bearing. | Check for looseness or corrosion on the bolts. | Movement of the driveshaft during operation. |

Maintenance Tips for Extending Center Bearing Lifespan

Maintaining the center bearing in your vehicle is crucial for a smooth ride. It supports the driveshaft and ensures proper alignment. Regular inspections can prevent costly repairs. Look for signs of wear, like unusual noises or vibrations. A little attention now can save you from bigger problems later.

Lubrication is key to longevity. Use the recommended grease type for optimal performance. Over-lubrication can attract dirt and debris, causing damage. Keep an eye on seals to prevent fluid leaks. Address any issues right away to avoid further stress on the bearing.

Don’t overlook tire alignment. Misalignment can put extra pressure on the center bearing. If you notice uneven tire wear, it’s time for a check-up. Remember, a proactive approach can lead to better vehicle performance. Regular maintenance isn’t just good practice; it’s essential for your safety and comfort on the road.

When to Replace a Center Bearing: Signs and Recommendations

Center bearings play a crucial role in a vehicle’s drive shaft system. They help support the drive shaft and reduce vibrations. Knowing when to replace a center bearing can save you from costly repairs and ensure a smoother ride.

One sign of wear is unusual vibrations while driving. If you feel excessive shaking, it could be a center bearing issue. Listen for any grinding or knocking noises as well. These sounds might indicate that the bearing is failing. If you notice these symptoms, check your vehicle soon.

Here are some tips for maintaining your center bearing: Regularly inspect the bearing for wear and tear. Lubricate it as needed to ensure smooth operation. Additionally, keep an eye on your drive shaft alignment. Misalignment can lead to premature wear. Remember, ignorance can lead to bigger problems. Taking proactive measures can enhance your vehicle’s performance.

Understanding Center Bearing in Vehicles

This chart presents the various signs indicating potential issues with the center bearing in vehicles. Monitoring these symptoms can help in determining when to replace or service the center bearing to maintain optimal vehicle performance.