2026 Best Alloy Powder Grader Reviews and Buying Guide?

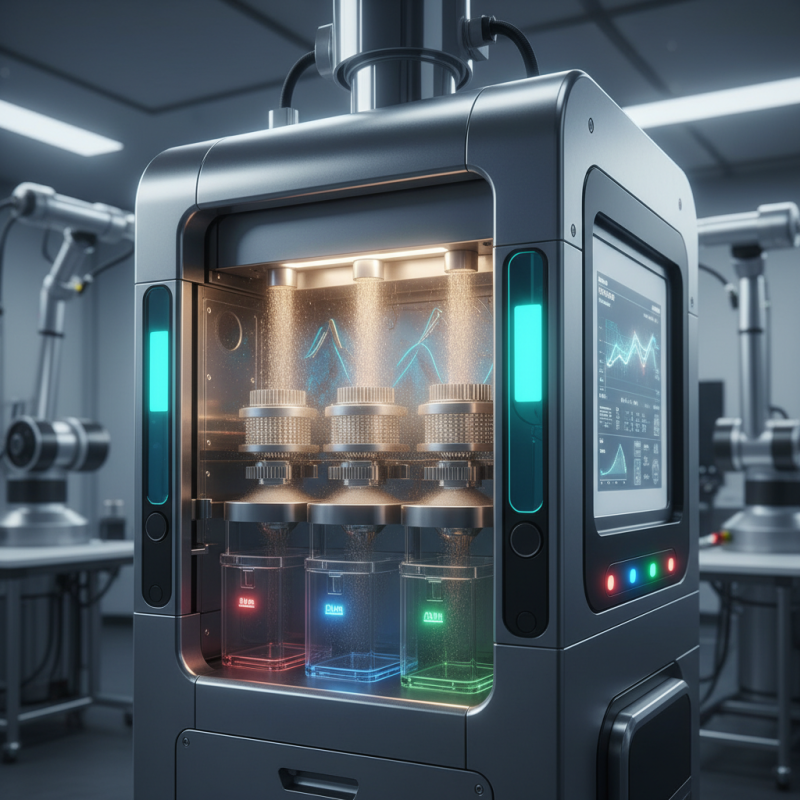

In the rapidly evolving field of materials science, the role of an Alloy Powder Grader is increasingly significant. According to recent industry reports, the global metal powder market is projected to reach $6.9 billion by 2026. This growth reflects the demand for high-quality alloy powders across various sectors, including aerospace, automotive, and additive manufacturing.

Choosing the right Alloy Powder Grader can be overwhelming. There are numerous options available, each with its unique features and specifications. A good grader should ensure precision in particle size distribution. However, not all graders meet this standard. Some users have reported inconsistencies in the grading process, leading to material waste and production delays.

The right Alloy Powder Grader can enhance efficiency and improve product quality. Yet, users must be cautious of potential pitfalls when making their choice. They should seek graders that offer both accuracy and reliability. Ultimately, innovative grading solutions will pave the way for advancements in alloy applications and production methodologies.

2026 Overview of Alloy Powder Graders: Key Features and Benefits

Alloy powder graders play a crucial role in the manufacturing and metalworking industries. Their importance cannot be overstated. These graders ensure that alloy powders meet the specified particle size distributions. This precision impacts the performance of the end products significantly. According to recent industry reports, nearly 40% of production defects are linked to improper particle sizing.

Key features to consider include adjustable grading settings and high throughput rates. Efficient graders can process large volumes quickly, vital in high-demand environments. For example, top-tier alloy powder graders can handle 500 kg per hour. This efficiency not only boosts productivity but also minimizes waste during production. However, choosing the right model can be overwhelming due to the variety available.

Benefits extend beyond mere efficiency. Quality graders can lead to enhanced mechanical properties of alloys. When powders are graded correctly, the final products exhibit better strength. Yet, some users report difficulties in calibrating machines. Frequent adjustments may be needed to maintain accuracy. It raises questions about reliability and ease of use. Users must weigh these factors carefully when selecting equipment.

Current Trends in Alloy Powder Grading Technologies and Materials

Alloy powder grading technologies are evolving rapidly. This field focuses on the precise measurement of particle size and distribution of alloy powders. Accurate grading is crucial for industries like aerospace and automotive. New advancements are allowing for better efficiency and less waste.

One key trend is the use of automated systems. These systems offer faster results and improved accuracy. However, they can be expensive and require careful calibration. Keep in mind that training staff on new technologies is also essential. Investing in good training pays off in better results.

Tips: Look for user-friendly options when selecting grading equipment. Ensuring easy maintenance is also critical. Review feedback from other users when considering a product. Regular calibration checks help maintain accuracy while preventing potential issues in grading processes.

Comparative Analysis of Top Alloy Powder Graders on the Market

When exploring alloy powder graders, it's essential to consider their efficiency and accuracy. Different models vary significantly in their measurement capabilities. Some may excel in speed, while others focus on precision. This creates a dilemma. How do you prioritize which feature is most important for your needs? The user experience can vary widely based on these factors.

Another consideration is adaptability. Certain graders work better with specific alloys, while others may struggle. This inconsistency can lead to unexpected frustrations during projects. Users need to evaluate their alloy types before selecting a grader. Ease of use is critical as well. Some devices are user-friendly, but others require a steep learning curve. Thus, looking for intuitive designs can save valuable time.

Lastly, the price point is often a challenge. Higher costs may not always equal better performance. Some affordable options might surprise users with their reliability. Exploring comparative reviews could illuminate these disparities. It's worth pondering: could a less expensive model meet your needs just as well? You might discover that diving deeper into the specifications will yield better insights than surface-level comparisons.

Essential Factors to Consider When Buying an Alloy Powder Grader

When looking for an alloy powder grader, various factors come into play. The grading capacity is crucial. It determines how much powder you can grade in one cycle. A larger capacity can save time but may require more space. Equally important is the accuracy of the grading. A device that isn’t precise can lead to inconsistent results. This could affect your final product quality.

Consider the material construction of the grader. High-quality materials ensure durability and longevity. Cheaper models might save money initially but could end up costing more in repairs or replacements. The size and portability of the machine should also be factored in. Smaller graders may be easier to store but can limit your options for larger projects.

Don't overlook the ease of use. Complexity can become a hurdle, especially for newcomers. Look for features that enhance user experience. Sometimes, a simple interface works better than a complicated one. Maintenance requirements are another aspect to think about. Some machines need regular upkeep, while others may only require minimal attention. Balancing these factors can refine your choices and potentially lead to a better purchase.

2026 Best Alloy Powder Grader Comparison

Expert Recommendations for Maintaining Alloy Powder Graders for Longevity

Maintaining alloy powder graders is crucial for their longevity and performance. Regular upkeep helps prevent costly repairs down the line. Ensure the components are clean and free from contamination. Dust and debris can affect accuracy. Lubricate moving parts regularly to minimize wear and tear.

Tips: Check for clogs in the feed system. A blockage can slow down operations. Keep an eye on the calibration. Regular calibration maintains precision. Additionally, monitor any unusual noises during operation. This can signal potential issues.

Routine inspections are vital. Look for rust or corrosion on key parts. These can compromise the machine's efficiency. Don't overlook the importance of user manuals. They often contain specific maintenance advice. Remember, even small adjustments can lead to significant improvements. It's easy to overlook details, but they matter.