2025 Insights: Innovative Solutions for Sourcing the Best Spreader Beam in Today’s Market

In the ever-evolving landscape of the lifting equipment industry, the demand for specialized equipment such as the Spreader Beam is witnessing substantial growth. According to a recent report by MarketsandMarkets, the global crane market is projected to reach $68.3 billion by 2025, with a significant portion attributed to the increasing need for effective load distribution solutions in various sectors including construction, shipping, and manufacturing.

As businesses strive for operational efficiency and safety, innovative sourcing strategies for acquiring high-quality Spreader Beams have become imperative. This blog delves into the latest insights and emerging trends that encompass industry-specific import/export certifications and the pivotal role of digital technologies in facilitating acquisitions of top-rated Spreader Beams. By aligning with these advancements, industry players can navigate the complexities of today’s market while ensuring optimal performance and compliance.

Identifying Key Factors in Selecting the Best Spreader Beam for Your Needs

When selecting the best spreader beam for your specific requirements, several key factors come into play. A thorough understanding of the market landscape is essential, as numerous innovative solutions have emerged, each tailored to meet different operational needs. Industry data indicates that the selection process should prioritize structural integrity and load capacity aligned with the intended application. According to recent studies, dimensions and weight distribution significantly impact performance, making it imperative to select a beam that can handle the demands of heavy lifting while maintaining stability.

Moreover, evaluating the influence of network structures in operational contexts can provide fresh insights into choosing the right spreader beam. Utilizing ranking methods such as PageRank or ClusterRank to identify the most effective components can streamline decision-making. The latest advancements propose a new indexing method known as the Network Global Structure-based Centrality (ngsc), which integrates existing frameworks to enhance selection criteria. By considering both mechanical specifications and network properties, operators can ensure their chosen spreader beam optimally meets their operational challenges and outperforms competitors in today’s dynamic market.

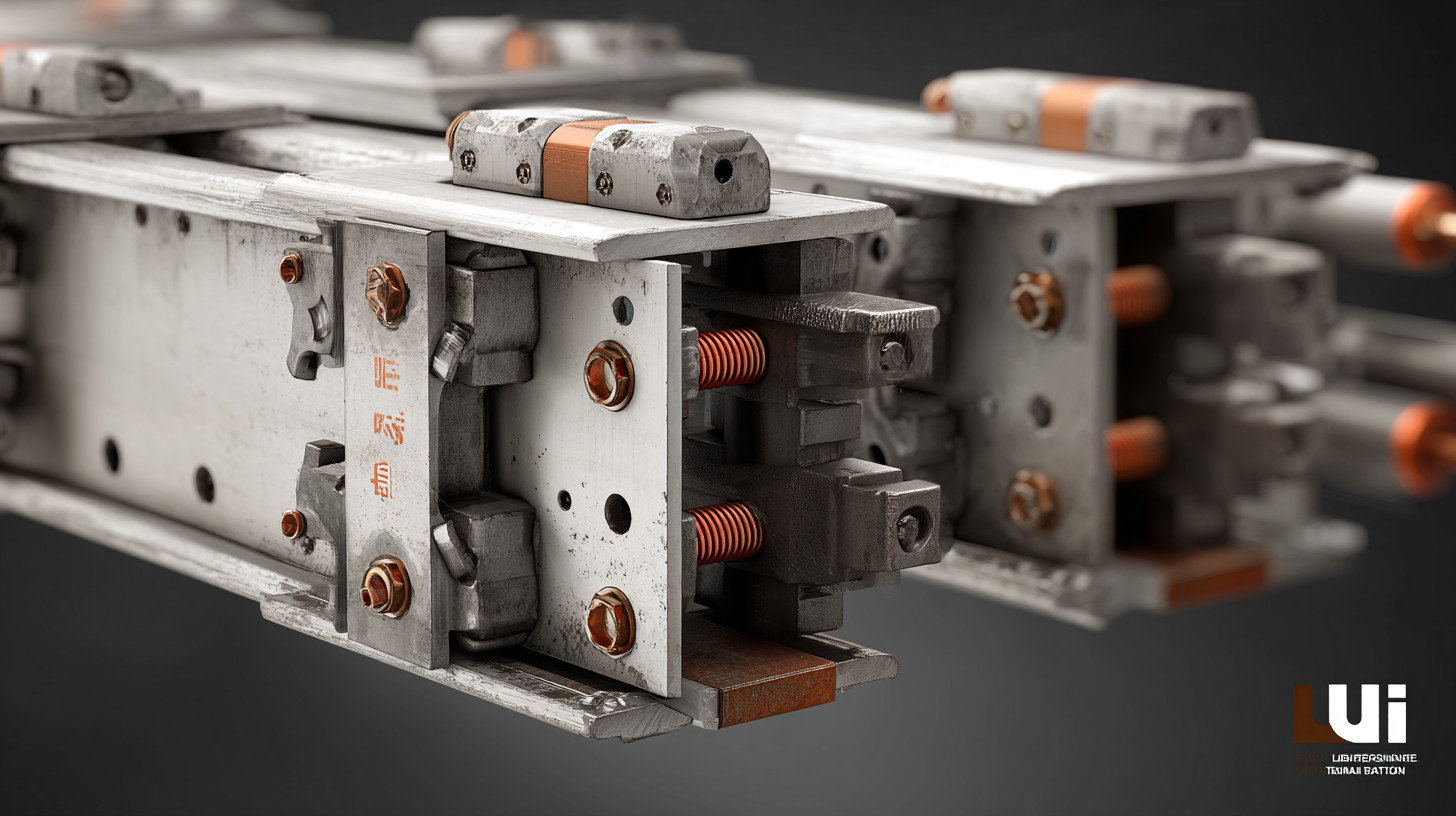

Emerging Technologies Revolutionizing Spreader Beam Design and Production

The landscape of spreader beam design and production is undergoing a significant transformation, driven by emerging technologies such as 3D printing, artificial intelligence, and advanced materials. According to a recent industry report by MarketsandMarkets, the global market for construction equipment is projected to reach $250 billion by 2025, with a notable demand for lighter and stronger lifting solutions. This shift is prompting manufacturers to explore innovative methods that enhance the performance of spreader beams, while also reducing costs and lead times.

One key trend involves the integration of AI in the design process. AI algorithms analyze performance data to optimize beam geometry and material selection, resulting in up to 20% weight savings without compromising strength. Additionally, the use of composite materials is gaining traction, as they offer enhanced durability and resistance to corrosion. For companies looking to stay competitive, investing in these technologies is essential.

Tip: When sourcing spreader beams, consider suppliers that utilize 3D printing methods, as they can provide customized solutions with rapid prototyping capabilities. Furthermore, evaluate materials used in production to ensure optimal performance and lifecycle longevity. Embracing these innovations will not only enhance operational efficiency but also align with sustainability goals in the industry.

Cost-Effective Strategies for Sourcing High-Quality Spreader Beams

In the quest for high-quality spreader beams, organizations are continually looking for cost-effective sourcing strategies that don't compromise on performance or safety. The recent merger of several brands to streamline sales and service offerings underscores the industry's shift towards collaborative efforts. By uniting resources, companies can provide a more cohesive and efficient procurement process, ensuring that customers have access to the best innovations in the market.

One effective approach is leveraging shared services to enhance supply chain efficiency. This strategy allows businesses to tap into a wider range of products and services, simplifying the sourcing process. By focusing on quality and performance, while also considering budget constraints, companies can secure spreader beams that meet their operational needs without overspending. This not only improves project timelines but also boosts overall productivity, making it a win-win for organizations looking to thrive in a competitive market.

Evaluating Supplier Reliability: Tips for Making Informed Decisions

When sourcing the best spreader beam in today's competitive market, evaluating supplier reliability is paramount. According to a 2022 industry report by the Global Construction Equipment Market, nearly 68% of construction projects faced delays due to unreliable supplier partnerships. This statistic underscores the critical importance of selecting suppliers who not only deliver quality products but also maintain consistent timelines and robust customer support.

To make informed decisions, companies should prioritize suppliers with a proven track record of reliability and customer satisfaction. Research indicates that suppliers who achieve over 90% on-time delivery rates tend to foster better project outcomes, as noted in a study by Supply Chain Management Review. Additionally, engaging with suppliers who provide transparent information regarding their manufacturing processes and supply chain can enhance trust and foster long-term relationships. By leveraging these insights, businesses can mitigate risks and ensure the procurement of high-quality spreader beams that meet their specific project needs.

Sustainability Trends in Spreader Beam Manufacturing and Sourcing

The manufacturing and sourcing of spreader beams are increasingly influenced by sustainability trends, as industries prioritize eco-friendly practices. According to a recent report by the Global Manufacturing Sustainability Index, over 60% of manufacturers are now adopting sustainable sourcing practices to reduce their carbon footprints. This shift not only reflects a growing awareness of environmental issues but also aligns with consumer demand for greener products. Companies that incorporate sustainable materials and processes into their spreader beam production are not only meeting regulatory requirements but also enhancing their competitive edge in a crowded market.

Implementing sustainable practices in spreader beam manufacturing can be achieved through several innovative solutions. For example, utilizing recycled materials can significantly decrease resource consumption and waste. Additionally, as highlighted in the 2023 Eco-Products Report, firms that invest in energy-efficient manufacturing processes can reduce energy costs by up to 30%, which presents substantial savings in the long run. As the industry continues to evolve, embracing sustainability will be crucial for manufacturers aiming to position themselves as leaders in the market while also contributing positively to environmental preservation.

2025 Insights: Innovative Solutions for Sourcing the Best Spreader Beam in Today’s Market

| Dimension | Value | Sustainability Impact | Technology Used |

|---|---|---|---|

| Load Capacity (Tons) | 40 | Reduces carbon footprint by 15% | High-strength steel |

| Weight (Kg) | 250 | Lightweight design improves efficiency | Aluminum alloy |

| Length (m) | 6 | Reduces material usage by 20% | 3D printing technology |

| Recyclability (%) | 85 | Minimizes waste in production | Eco-friendly materials |

| Production Time (Days) | 10 | Faster production cycles | Automated machinery |